Zhengli are the leading of Tubular Vials manufacture in China.Including Freeze drying Vials,concave convex mouth Vials,Screw mouth Vials,leakproof Vials,Gland Vials and so on.All the Zhengli Tubular Vials and Package processing are carry out ISO9001 and ISO 15378 standard strictly.

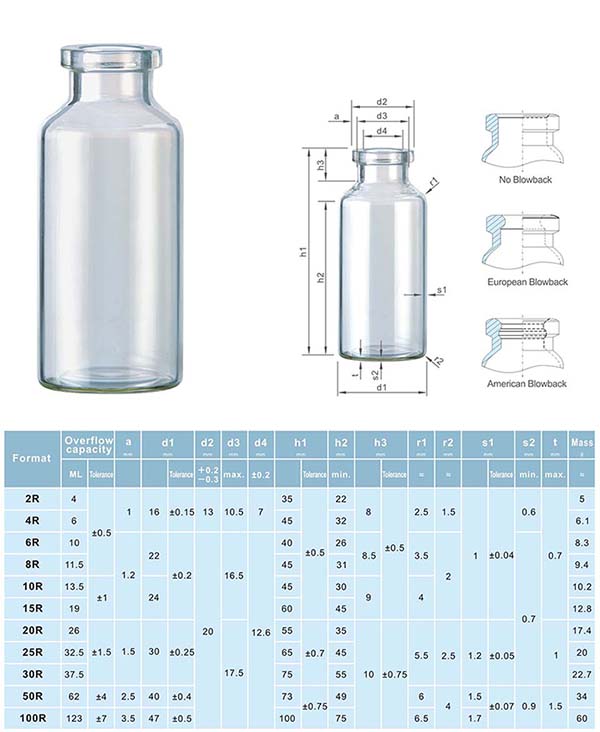

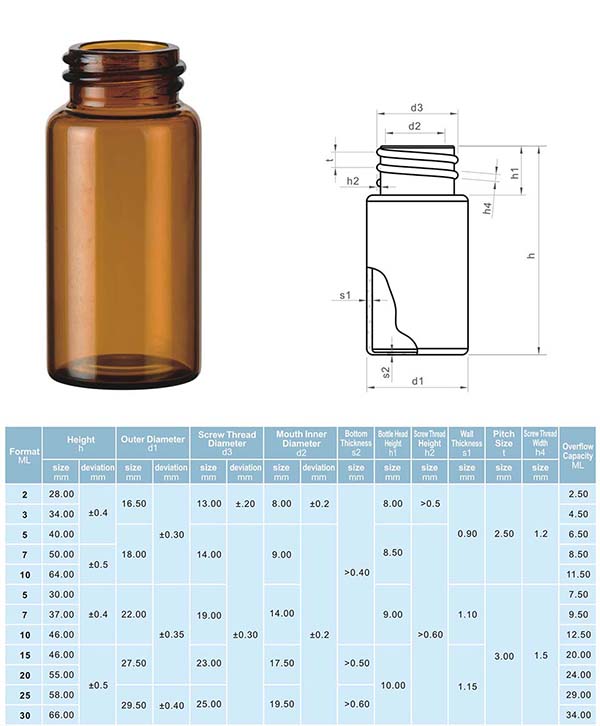

· Products Name: Injection Tubular vials

· Materials: Tubular Glass type I

· Application : Medical, Cosmetic, Ophthalmology, Laboratory.

· Brand Name : ZhengLi

· Processing Technology : High temperature

· Quality : : Superior

· Hardness : Strong

· Compressive Stength : Strong

· Water tightness : Strong

· Linear thermal expansion coefficient : 3.5 - 6.1 x 10-6K -1 ( 20-300' C )

· 121'C hydrolytic resistance of glass grain : Grade 1

· 98'C hydrolytic resistance of glass grain : HGB1

· Hydrolytic resistance of interior surfaces : HC1

Products Description:

Tubular Glass Vials

Zhengli keep constantly create competitive value for our customer. Continuous technological innovation and products upgrading that enable us to offer comprehensive solutions to meet different market demands..

With more than 25 years of technology accumulation and technology optimization, Zhengli become the leading of tubular Vials manufacturer in China pharmaceutical market.

The Tubular Vials include freeze-drying Vials, convex concave Vials, screw neck Vials, leakproof Vials and gland Vials. The products and its packaging are strictly carry out ISO 9001 and ISO 15378 standard.

· GMP environment plant

· 100% AIS dimensional and cosmetic inspection

· 100% traceability of products

· Lyophilization

· Sterilization

· Ready to fill&finish

If need special request,most welcome to contact us.

Glass Tubing Raw Materials date list :

Physical Parameters | Linear Thermal expansion coefficient | |

α(20°C; 300°C) ISO 7991 | 4.9 ? 10-6K -1 | |

Disguised Point | 565 °C | |

Glass Viscosity ηin dPa . s | ||

1013 (Annealing Point) | 565 °C | |

107.6 (Softening Point) | 785 °C | |

104(Working Point ) | 1160 °C | |

Density ρ at 25°C | 2.34 gNaN-3 | |

Chemical Parameters | Hydrolytic resistance ISO 719 | HGB 1 class |

Acid Resistance DIN 12116 | S 1 class | |

Alkali Resistance ISO 695 | A 2 class | |

ASTM E 438 | B class | |

Percentage of Chemical Composition

| SiO2 | 75% |

B2O3 | 10.5% | |

Al2O3 | 5% | |

Na2O | 7% | |

CaO | 1.5% | |

WeChat QR Code

WeChat QR Code